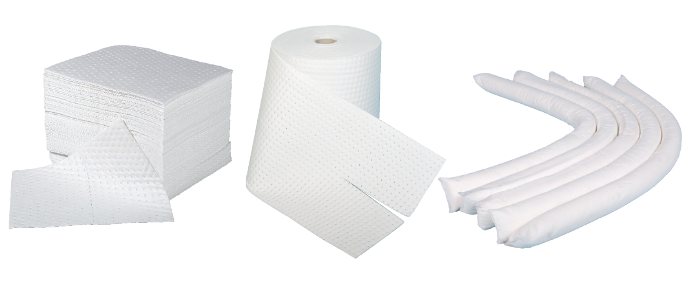

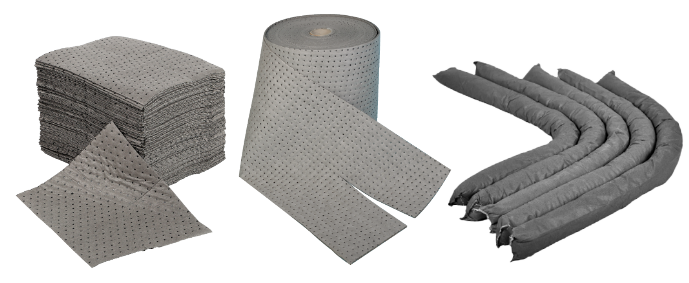

Absorbents come in many shapes and sizes and are a great alternative to granular material that can cause cross contamination.

Absorbent Pads and Absorbent Rolls can be used as a work-mat to catch and absorb drips and leaks during component maintenance and cleaning

Absorbent Pads and Absorbent Rolls can be used as a work-mat to catch and absorb drips and leaks during component maintenance and cleaning

Absorbent Cushions for use in drip trays to absorb leaked fluids easily and efficiently and to reduce further spillage during disposal of drip tray contents.

Absorbent Socks can be placed at the base of leaking machinery to absorb leaks on contact and reduce the spread of contamination or use to surround a spillage to prevent further spreading and absorb on contact.

We are constantly developing absorbents for new and existing problems.

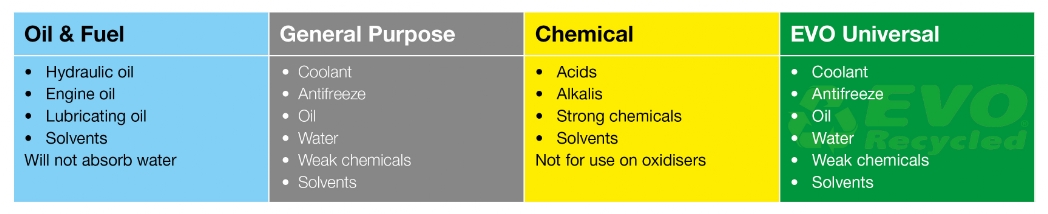

EVERYDAY OIL AND FUEL ABSORBENTS

- For oils, fuels and solvents

- Hydrophobic - will not absorb water

- Can be used in wet weather

- Ideal in marine applications, eg. ponds, streams, harbours

- Used widely in manufacturing industry

HYDRAULIC ABSORBENTS

Hydraulic absorbents have an open, non-bonded finish that mops up oil fast, ideal for use with hydraulic oils. These pads and rolls also have a hydrophobic coatings which means they can be

used outside without absorbing water.- For oils, fuels and solvents

- Hydrophobic - will not absorb water

- Can be used in wet weather

GENERAL PURPOSE/COMMON LIQUID ABSORBENTS

- For common workshop and engineering fluids products and other non-harmful liquids

- Unsuitable for acids and caustics

- Compatible with water, milk, food

CHIMICAL ABSORBENTS

- Compatible with strong chemicals

- Stable in acids and caustics

- Will also absorb non-aggressive liquids

UNIVERSAL ABSORBENTS

- Recycled natural fibres

- Universal absorbent

- Lowest carbon footprint on the market

- Sustainable

- Environmentally friendly

WHY YOU NEED SPILL CONTROL

• Compliance with regulations

• Internal environmental/safety standards

• Compliance with ISO14001

• Insurance liability

• Duty of care

Pollution Prevention Guidelines

PPG26 states the requirement to have Spill Kits on site to respond to any spills. Spill Kits containing plugging compound, drain protection and oil or chemical absorbents should be on site. All staff should be trained in the use of this equipment. It is also recommended that vehicles transporting drums and IBCs carry a spill kit.

ISO 14001

Adequate spill protection equipment must be on hand.

Staff should be trained to use the equipment to protect the environment in the event of an accidental spillage.

Considerate Constructors Scheme

Environmental Checklist

Have any surface water drains been identified and sealed off?

Has a material storage area been identified?

Will drip trays, or similar, be provided for static plant equipment?

Are spill kits available and do employees know how to use them?

Have employees been trained in emergency spill response?